Is your washing machine acting up, leaving you with a laundry room full of sopping wet clothes and a growing sense of frustration? Perhaps you've noticed it's taking forever to fill, or worse, overflowing and creating a mini indoor pool. Before you resign yourself to hauling your laundry to the laundromat, there's a good chance the culprit is a faulty water inlet valve. Don't panic! This isn't necessarily a task that requires a professional, and with a little know-how, you might be able to tackle it yourself.

Dealing with appliance malfunctions can be incredibly disruptive. The inconvenience of a broken washing machine extends beyond just clean clothes. It throws off your schedule, adds unexpected expenses to your budget, and can even lead to water damage if left unaddressed. Figuring out the source of the problem and deciding whether to repair or replace can be overwhelming, especially if you're not mechanically inclined.

This guide is designed to empower you with the knowledge and confidence to troubleshoot and potentially replace your washing machine's water inlet valve. We'll walk you through the process step-by-step, covering everything from identifying the symptoms of a faulty valve to the actual replacement procedure. Whether you're a seasoned DIY enthusiast or a complete beginner, this resource will help you determine if this is a repair you can handle yourself, saving you time and money.

In this comprehensive guide, we will explore the common symptoms of a failing washing machine water inlet valve, providing a detailed, step-by-step troubleshooting process. We'll delve into the necessary tools and safety precautions, offer practical repair instructions and then further expand into the intricacies of Washer Water Valve Replacement: Troubleshooting and Fix Guide and related keywords.

Identifying a Faulty Water Inlet Valve: Signs and Symptoms

The goal here is to equip you with the knowledge to accurately diagnose a water inlet valve issue. Recognizing the signs early on can prevent further damage and save you from unnecessary repair costs. Think of it as becoming a detective, investigating the clues your washing machine is leaving behind. I remember the first time I suspected an issue with my own washing machine's water valve. It started with the machine taking an abnormally long time to fill with water. I initially dismissed it, thinking perhaps the water pressure was low that day. But the problem persisted, and soon I noticed the water trickling in, barely a stream. That’s when I knew something was seriously wrong. So, what are the telltale signs? Look out for these common indicators: slow filling, no filling at all, continuous filling even when the machine is off, weak water pressure during the fill cycle, or unusual noises coming from the valve area during operation. Often, these symptoms are accompanied by error codes displayed on the washing machine's control panel, which can provide additional clues. It is important to check the water hoses for kinks or clogs, as these can mimic valve problems. In most modern washing machines, the inlet valve assembly is easily accessible by removing the top or back panel. Always disconnect the power before beginning any inspection or repair. To test the valve, you can use a multimeter to check for continuity. A functioning valve should show a specific resistance reading, indicating the coil is intact. If the valve shows no continuity, it needs to be replaced. These valves are usually inexpensive and easy to find at appliance repair stores or online retailers. Replacing the valve is a simple process. Start by shutting off the water supply to the machine, then disconnect the hoses from the old valve. Next, disconnect the electrical connections and remove the old valve from its mounting. Install the new valve by reversing these steps. Be sure to tighten all connections securely to prevent leaks.

Tools and Materials You'll Need

Understanding the right tools and materials needed is crucial for a successful repair. It’s like preparing for a recipe – having all the ingredients and utensils readily available makes the cooking process much smoother and more efficient. When it comes to replacing a washing machine water inlet valve, you don’t need an extensive toolbox, but having the essentials will make the job significantly easier and safer. Think of these as your essential allies in the repair process. At the bare minimum, you'll need a screwdriver (both Phillips head and flathead, depending on your machine's construction), a pair of pliers, and an adjustable wrench. These will be used for removing panels, disconnecting hoses, and loosening connections. A multimeter is also invaluable. As mentioned earlier, it is used for testing the electrical continuity of the valve coils, helping you determine if the valve is truly faulty. In addition to these tools, you'll need a few essential materials. Of course, the most important item is the replacement water inlet valve itself. Be sure to purchase the correct valve for your washing machine model to ensure compatibility. You might also want to have some Teflon tape on hand. This tape is used to seal the threads of the water hose connections, preventing leaks. A small bucket or towels are necessary to catch any water that spills when you disconnect the hoses. Safety is key when working with electrical appliances, so always wear gloves to protect your hands and eye protection to shield your eyes from any debris. Before you start, take a moment to gather all your tools and materials and create a clean, well-lit workspace. This will help you stay organized and focused, making the repair process more efficient and safer. If you are not confident with electrical testing, it’s always a good idea to consult a professional.

Safety First: Important Precautions

Prioritizing safety is non-negotiable when dealing with electrical appliances and plumbing. Think of it as wearing a seatbelt before driving – it's a simple precaution that can prevent serious injury. Many people underestimate the risks involved in DIY repairs, especially when water and electricity are involved. Failing to take proper precautions can lead to electric shock, water damage, or even injury from mishandling tools. It is important to always disconnect the washing machine from its power source before starting any repair work. This eliminates the risk of electrical shock and ensures that you can work safely without worrying about accidental activation of the machine. Turn off the circuit breaker that supplies power to the washing machine or unplug it from the outlet. Water is an excellent conductor of electricity, so water leaks during the repair process can create a serious hazard. Shut off the water supply to the washing machine before disconnecting any hoses. This will prevent water from spraying out when you detach the hoses from the water inlet valve. Even after turning off the water supply, there may still be residual water in the hoses and valve. Place a bucket or towels underneath the connections to catch any drips. When working with tools, always wear gloves to protect your hands from sharp edges or rough surfaces. Eye protection is also essential to shield your eyes from any debris or splashes. Follow the manufacturer's instructions for your washing machine and the replacement water inlet valve carefully. The instructions provide valuable information about the repair process and any specific safety precautions that should be taken. If you are unsure about any aspect of the repair, don't hesitate to seek professional assistance. It's always better to err on the side of caution when dealing with electrical appliances and plumbing.

Step-by-Step Replacement Guide

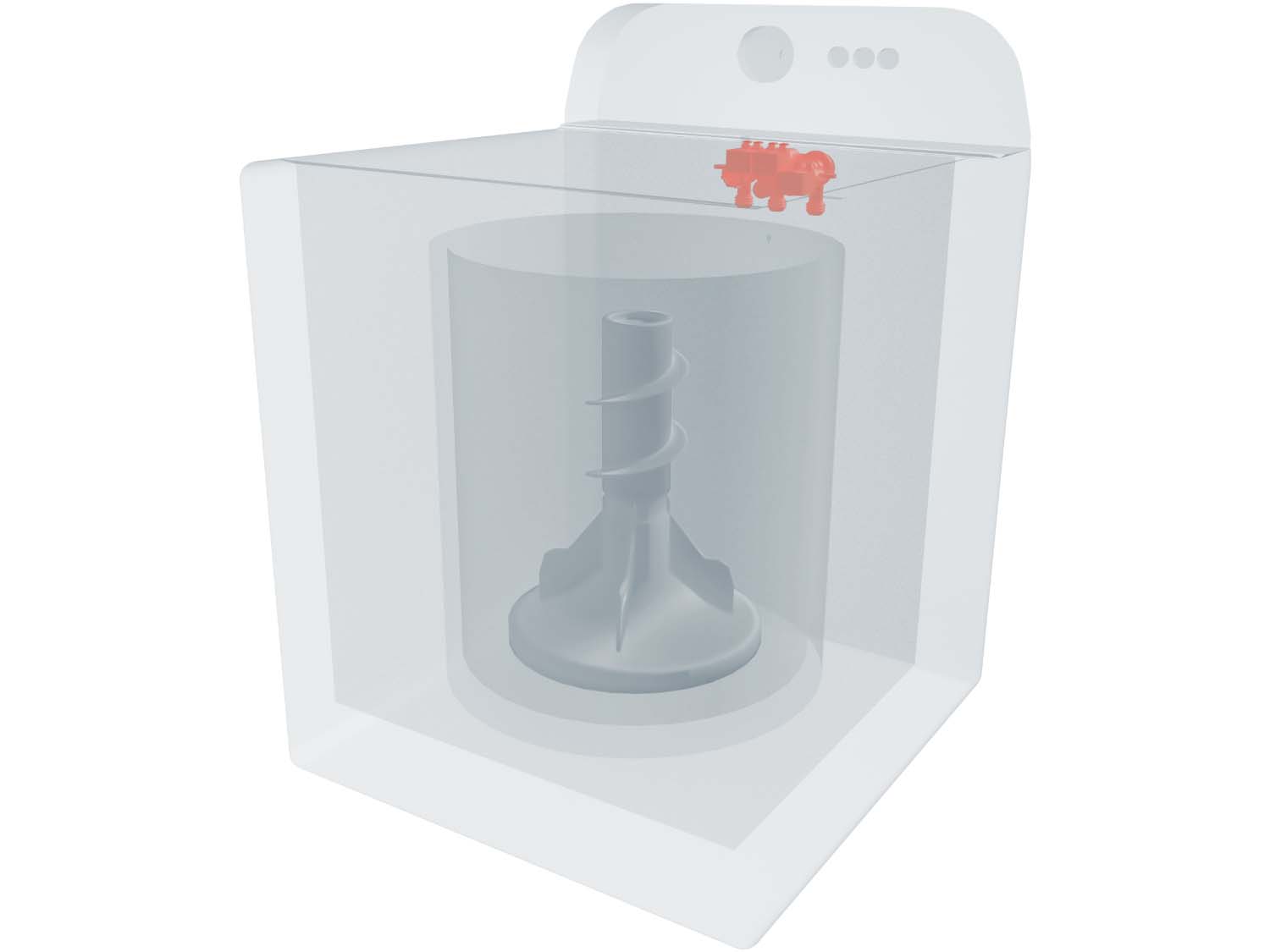

Following a structured approach ensures a smooth and successful replacement. Think of it as following a roadmap – each step brings you closer to your destination. Replacing a washing machine water inlet valve might seem daunting at first, but by breaking it down into manageable steps, you can tackle it with confidence. Start by gathering all the necessary tools and materials and preparing your workspace. Disconnect the washing machine from the power source and turn off the water supply. Locate the water inlet valve. It's usually at the back of the machine where the water hoses connect. Remove the washing machine's access panel to gain access to the valve. This panel may be on the top or back of the machine, depending on the model. Use a screwdriver to remove any screws or clips holding the panel in place. Once the access panel is removed, carefully disconnect the water hoses from the water inlet valve. Place a bucket or towels underneath the connections to catch any drips. Use a wrench to loosen the hose connections and gently pull them off the valve. Take note of which hose connects to which inlet on the valve to ensure proper reconnection later. Disconnect the electrical connections to the water inlet valve. There will typically be two or more wires connected to the valve. Use pliers to gently pull the connectors off the valve terminals. Take a picture or make a note of the wire connections to ensure you reconnect them correctly. Remove the water inlet valve from its mounting. This may involve unscrewing it from the frame or unclipping it from a bracket. Carefully remove the old valve and set it aside. Install the new water inlet valve in the same position as the old one. Secure it to the frame or bracket using the appropriate screws or clips. Reconnect the electrical connections to the new water inlet valve. Use the picture or notes you took earlier to ensure you connect the wires to the correct terminals. Reconnect the water hoses to the new water inlet valve. Tighten the hose connections securely with a wrench, but be careful not to overtighten them, as this could damage the valve or hoses. Replace the washing machine's access panel and secure it with the screws or clips you removed earlier. Turn on the water supply to the washing machine and check for any leaks around the hose connections. If you see any leaks, tighten the connections further. Plug the washing machine back into the power outlet or turn on the circuit breaker. Run a test cycle to ensure the new water inlet valve is working properly. Monitor the water level in the drum to ensure the valve is filling and shutting off correctly. If the machine is running smoothly, you've successfully replaced the water inlet valve! If you encounter any difficulties or are unsure about any step in the process, don't hesitate to seek professional assistance.

Troubleshooting Common Issues After Replacement

Even after a successful replacement, unforeseen problems can arise. Think of it as proofreading your work – catching any errors before submitting the final version. Replacing a washing machine water inlet valve is a significant accomplishment, but it's important to be prepared for potential issues that may arise afterward. Troubleshooting these issues promptly can prevent further damage and ensure your washing machine operates smoothly. One common issue is water leaks around the hose connections. If you notice water dripping from the connections after the replacement, the first step is to tighten the connections further. Use a wrench to gently tighten the hose connections, but be careful not to overtighten them, as this could damage the valve or hoses. If tightening the connections doesn't solve the problem, you may need to replace the hose washers. Worn or damaged washers can cause leaks, so replacing them with new ones can often resolve the issue. Another possible issue is the washing machine not filling with water or filling very slowly. If this happens, check the water supply to the machine. Make sure the water supply valves are fully open and that there are no kinks or obstructions in the water hoses. It is important to clean the water inlet screens. These screens are located at the inlet connections and can become clogged with sediment or debris, restricting water flow. Remove the hoses from the water inlet valve and clean the screens with a brush or compressed air. If the washing machine is filling continuously, even when it's not running, the new water inlet valve may be defective. In this case, contact the supplier or manufacturer for a replacement valve. The replacement valve may be the wrong part. Always verify the part number and compatibility before installing a new valve. If you're experiencing any other unusual symptoms or error codes, consult the washing machine's user manual for troubleshooting guidance. If you're unable to resolve the issue yourself, don't hesitate to seek professional assistance from a qualified appliance repair technician.

When to Call a Professional

Knowing your limits is a sign of wisdom, not weakness. Think of it as consulting a specialist when your general practitioner can't diagnose the problem. While replacing a washing machine water inlet valve is a task that many homeowners can handle themselves, there are situations where calling a professional appliance repair technician is the best course of action. If you're uncomfortable working with electrical appliances or plumbing, don't attempt the repair yourself. It's always better to err on the side of caution and seek professional assistance. If you're unable to diagnose the problem with your washing machine, a qualified technician can perform a thorough inspection and identify the root cause of the issue. This can save you time and money in the long run by preventing you from replacing parts unnecessarily. If you've attempted the replacement and are still experiencing problems, it's time to call a professional. The technician can troubleshoot the issue and determine if there's a more complex problem with your washing machine. If your washing machine is under warranty, attempting the repair yourself may void the warranty. Check the warranty terms and conditions to see if you need to use an authorized service provider for repairs. Look for a licensed and insured appliance repair technician with experience repairing washing machines. Ask for referrals from friends, family, or online review sites. Be sure to get a written estimate before authorizing any repairs. This will help you avoid any unexpected charges and ensure that you're getting a fair price for the service. Don't hesitate to ask the technician questions about the repair process and the parts they're using. A reputable technician will be happy to explain the work they're doing and answer any concerns you may have. When in doubt, it's always better to seek professional assistance from a qualified appliance repair technician. This can ensure that the repair is done correctly and safely, protecting your washing machine and your home from further damage.

Tips for Preventing Future Water Inlet Valve Problems

Proactive maintenance can save you from future headaches. Think of it as brushing your teeth – a simple habit that prevents costly dental work. Preventing future problems with your washing machine's water inlet valve is about proactive maintenance and adopting good habits. These steps can help extend the life of your valve and avoid costly repairs. One of the most important things you can do is to install a water softener if you have hard water. Hard water contains minerals that can build up inside the water inlet valve and cause it to malfunction. A water softener removes these minerals, preventing them from causing problems. Regularly clean the water inlet screens. These screens are located at the inlet connections and can become clogged with sediment or debris, restricting water flow. Inspect the water hoses regularly for kinks, cracks, or other damage. Replace damaged hoses immediately to prevent leaks or other problems. Avoid overloading your washing machine. Overloading can put stress on the water inlet valve and other components, leading to premature failure. Use the correct amount of detergent for each load. Excessive detergent can cause buildup in the water inlet valve and other parts of the washing machine. When you're not using your washing machine for extended periods, such as when you're on vacation, turn off the water supply to the machine. This will help prevent leaks or other problems. Follow the manufacturer's recommendations for maintenance and care. These recommendations are designed to keep your washing machine running smoothly and prevent problems. Take a moment to read the user manual and familiarize yourself with the recommended maintenance schedule. By following these tips, you can help prevent future problems with your washing machine's water inlet valve and keep your machine running smoothly for years to come.

Understanding Your Washing Machine Model

Every washing machine is unique, like a fingerprint. Think of it as knowing the specific ingredients in your favorite dish. Understanding your washing machine model is essential for effective troubleshooting and repair. Each model has its own specific features, components, and quirks, so knowing the details of your machine can save you time and frustration. Look for the model number on your washing machine. The model number is usually located on a sticker or plate on the back of the machine, inside the door, or on the control panel. Once you have the model number, you can use it to find information about your washing machine online or in the user manual. The user manual is a valuable resource for troubleshooting problems and performing maintenance. It contains information about the machine's components, operation, and troubleshooting tips. Look for diagrams and illustrations of the washing machine's components. These diagrams can help you locate the water inlet valve and other parts of the machine. Take the time to read the troubleshooting section of the user manual. This section provides information about common problems and how to resolve them. If you can't find the user manual, you can often download it from the manufacturer's website. Search for the user manual using the model number of your washing machine. Be aware of any specific features or settings that may affect the operation of the water inlet valve. For example, some washing machines have a water-saving feature that can affect the water level in the drum. By understanding your washing machine model, you can troubleshoot problems more effectively and perform repairs with greater confidence. The model number, user manual, and component diagrams can all provide valuable information that will help you keep your washing machine running smoothly.

Fun Facts About Washing Machines

Appreciating the evolution of laundry is surprisingly interesting. Think of it as learning the backstory of a beloved character in a movie. Washing machines have a rich and fascinating history, and learning a few fun facts about them can give you a new appreciation for this essential appliance. The earliest washing machines were invented in the 18th century. These early machines were hand-powered and often used a wooden tub and a crank-operated agitator. The first electric washing machine was invented in 1908 by Alva J. Fisher. This invention revolutionized the laundry process and made it much easier for people to wash their clothes. The spin cycle, which removes excess water from clothes, was invented in the 1930s. This feature significantly reduced the drying time for laundry. During World War II, washing machine production was limited due to the war effort. After the war, there was a surge in demand for washing machines as people sought to modernize their homes. The development of synthetic fabrics in the mid-20th century led to the development of new washing machine cycles and features. These cycles were designed to handle the unique properties of synthetic fabrics. Today, washing machines are available in a wide variety of styles and sizes, from compact models for apartments to high-capacity machines for large families. Smart washing machines are equipped with features such as Wi-Fi connectivity and mobile app control. These machines can be programmed to run remotely and can even alert you when your laundry is done. The average washing machine lasts for about 10-12 years with proper care and maintenance. Taking care of your washing machine can help extend its lifespan and prevent costly repairs. From hand-powered wooden tubs to smart, connected appliances, washing machines have come a long way. These machines have transformed the way we do laundry and have made our lives much easier.

How to Properly Dispose of the Old Valve

Responsible disposal protects the environment. Think of it as recycling – doing your part to keep the planet healthy. Properly disposing of the old water inlet valve is essential for protecting the environment and preventing pollution. Water inlet valves contain materials that can be harmful if not disposed of properly, so it's important to follow the correct procedures. Check with your local waste management authorities to determine the best way to dispose of the old water inlet valve. Some municipalities have specific regulations for disposing of electronic waste or appliance components. Contact your local recycling center to see if they accept water inlet valves. Many recycling centers accept electronic waste and will recycle the materials properly. Some appliance repair shops may also accept old water inlet valves for recycling. Check with local appliance repair shops to see if they offer this service. Do not simply throw the old water inlet valve in the trash. This can contribute to pollution and harm the environment. If you're unable to recycle the old water inlet valve, contact your local waste management authorities for guidance on proper disposal. They may have specific instructions or designated drop-off locations for electronic waste. Be sure to remove any water or debris from the old water inlet valve before disposing of it. This will help prevent leaks and contamination. Following these steps will ensure that you dispose of the old water inlet valve properly and help protect the environment. Responsible disposal is an important part of appliance repair and maintenance.

What if the New Valve Fails?

Having a contingency plan provides peace of mind. Think of it as having a spare tire in your car – you hope you don't need it, but you're glad it's there. Even after installing a new water inlet valve, there's always a chance that it could fail. Knowing what to do if this happens can save you time, money, and frustration. Contact the supplier or manufacturer of the new water inlet valve. Most valves come with a warranty, so you may be able to get a replacement valve free of charge. Before contacting the supplier or manufacturer, gather the following information: the model number of the new water inlet valve, the date of purchase, and a description of the problem. Check the washing machine's user manual for troubleshooting tips. The user manual may contain information about common problems and how to resolve them. Inspect the water hoses and connections to the new water inlet valve. Make sure there are no leaks, kinks, or other damage. Ensure that the water supply to the washing machine is turned on and that the water pressure is adequate. If the new water inlet valve is still not working, contact a qualified appliance repair technician. The technician can diagnose the problem and determine if there's a more complex issue with your washing machine. Don't attempt to repair the new water inlet valve yourself unless you're qualified to do so. This could void the warranty and potentially damage the valve or your washing machine. Keep records of all repairs and replacements. This will help you track the performance of your washing machine and identify any recurring problems. Having a contingency plan in place can help you deal with the unexpected and keep your washing machine running smoothly. By following these steps, you can minimize the impact of a failed new water inlet valve and get your washing machine back up and running quickly.

Top 5 Mistakes to Avoid During Water Valve Replacement

Learning from others' errors can save you from repeating them. Think of it as reading reviews before buying a product. Replacing a washing machine water inlet valve can be a straightforward process, but it's important to avoid common mistakes that can lead to problems. Here are the top five mistakes to avoid during water valve replacement: Failing to disconnect the power and water supply. Disconnecting the power and water supply is essential for safety. Neglecting to do so can result in electric shock or water damage. Not purchasing the correct replacement valve. Purchasing the wrong replacement valve can lead to compatibility issues and prevent the valve from working properly. Forgetting to label the wires before disconnecting them. Labelling the wires before disconnecting them ensures that you reconnect them correctly, preventing electrical problems. Overtightening the hose connections. Overtightening the hose connections can damage the valve or hoses, leading to leaks. Neglecting to test the new valve after installation. Testing the new valve after installation ensures that it's working properly and that there are no leaks or other problems. By avoiding these common mistakes, you can ensure a successful water valve replacement and keep your washing machine running smoothly. Taking the time to do the job right will save you time, money, and frustration in the long run.

Questions and Answers About Washer Water Valve Replacement

Let's address some frequently asked questions to solidify your understanding.

Q: How do I know if my washing machine water valve is bad?

A: Common signs include the washing machine filling slowly, not filling at all, continuously filling, or exhibiting weak water pressure during the fill cycle.

Q: Can I replace a washing machine water valve myself?

A: Yes, many homeowners can replace the water valve themselves, especially with the help of this guide. However, if you're uncomfortable working with electricity or plumbing, it's best to call a professional.

Q: Where can I buy a replacement water valve?

A: You can purchase replacement water valves at appliance repair stores, online retailers, or directly from the washing machine manufacturer.

Q: How much does it cost to replace a washing machine water valve?

A: The cost can vary depending on the valve type and whether you hire a professional. The valve itself typically ranges from $20 to $100, while professional installation can add another $50 to $150.

Conclusion of Washer Water Valve Replacement: Troubleshooting and Fix Guide

Replacing a faulty water inlet valve might seem intimidating, but with the right knowledge and preparation, it can be a manageable DIY project. This guide has equipped you with the necessary steps for troubleshooting, replacement, and ongoing maintenance. By understanding the symptoms, tools, and safety precautions, you can confidently tackle this repair and keep your washing machine running smoothly, saving you time and money. Remember to prioritize safety and seek professional help when needed, and you'll be well on your way to conquering this common appliance repair.